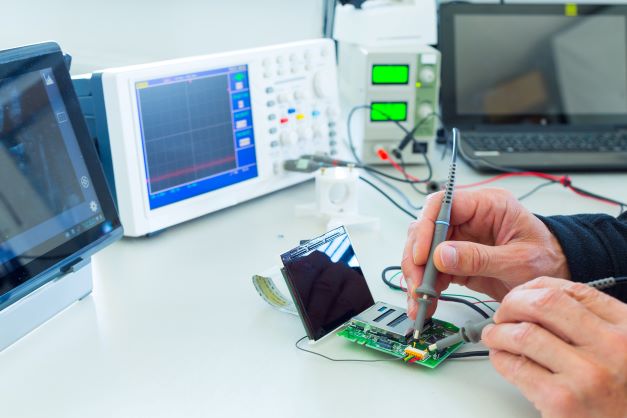

What is Medical Equipment Calibration?

Calibration of medical devices is performed to minimize any uncertainty in measurements that may be critical to patient care. It reduces errors by ensuring that measurements provide accurate results. These devices may be as complex as MRIs or medical lasers but may be as simple as thermometers or timing devices. Are you aware of the calibration requirements for the devices that your organization uses in patient care?

Medical Device Calibration Requirements

Over time and with repeated use, medical equipment performance can degrade in terms of accuracy and precision. With the criticality that measurements in medicine require, it is unacceptable if calibration is not maintained per the manufacturer’s instructions for use. Regular maintenance and service are needed for an instrument to work accurately and at its optimum. There are government regulations that establish the requirements for calibration. The Food and Drug Administration's (FDA) 21 CFR 11, 21 CFR 820, Quality System Regulation (QSR) and ISO 13485 provide mandates for calibration of medical devices. The FDA guidelines require that:

- Equipment calibration must be carried out routinely, as per the manufacturer’s instructions for use.

- Calibration of devices that needs to be calibrated must be documented.

- Acceptable limits for accuracy and precision must be specified.

- Staff performing calibration must be trained.

- Calibration standards must reference national standards, in-house standards (if necessary), or other acceptable standards.

- Actions for evaluating adverse effects caused by the defective equipment have been established and corrective measures taken when these occur.

The overarching CMS Condition of Participation §482.41(d)(2) states that “facilities, supplies, and equipment must be maintained to ensure an acceptable level of safety and quality”. Expectations of Accrediting Organizations are that health care facilities are ensuring their devices and equipment are functioning properly which would include maintaining them according to the instructions for use. Unfortunately, our observations have indicated that calibration of devices may not be considered in equipment maintenance activities.

Common Issues in Medical Equipment Calibration

Our team has made some observations in the field during mock surveys, regarding opportunities with calibration of equipment and devices. These may assist you in identifying where you may be experiencing alignment issues with calibration:

Thermometers

Observations of thermometers with expired calibration labels found within refrigerator/freezers used for nutrition, medication, tissue, and laboratory specimen storage. Similar findings have been found with thermometers used to measure Cidex OPA soaking reservoirs and IV/Irrigation Fluid warmers. These observations include both digital and analog thermometers.

Weight scales

Observations of patient and medication scales with expired calibration. These include both manual and digital devices.

Timers

Observations of timing devices with expired calibration used to determine soak times in Sterile Processing, laboratory testing, and other applications to measure time.

Detergent dispensers

Observations of chemical dosing devices that dispense detergents or other solutions for washers and soaking sinks in sterile processing without current calibration. Similar findings have been found associated with kitchen dishwashing equipment. These findings may lead to significant issues by a survey team due to the ramifications on infection prevention.

Laboratory testing

Organizations not following calibration and calibration verification procedures for laboratory equipment including waived testing devices. This includes observations of logs missing complete documentation and expired reagents for verification. See this link for CLIA’s brochure on calibration and calibration verification: https://www.cms.gov/files/document/clia-brochure-calibration-and-calibration-verification.pdf

Radiology equipment

Observations of radiology calibration reports not signed by the Medical Physicist to confirm review of the findings.

Pharmacy hoods and containment equipment

Observations of expired calibration and testing labels/documentation for hoods and containment devices used in compounding medications.

Microscopy

Observations of microscopes, often outside of the main laboratory, with expired calibration labels.

Addressing the Requirement

In addressing the number of calibration findings we are observing, we find that many organizations have not considered the calibration of devices and equipment in their routine preventive maintenance schedule. Often, organizations are not aware that these items require calibration, despite that many of them are labeled by the manufacturer as such.

We recommend that organizations review all equipment and device maintenance information for calibration requirements, especially those whose function is to provide measurement data. Identified requirements should be included in your preventive maintenance schedule plans. Furthermore, we recommend that if your organization labels devices with their preventive maintenance due dates, that devices which require calibration are labeled as well to provide staff with indications as to their readiness for use.

Staff should also be made aware of any implications for device usage that may alter an equipment item’s ability to provide accurate readings. This may include vibration, dropping the device, exposure to extreme temperatures or moisture. Users should be informed of any conditions that may affect function which may require re-calibration.

Summary

Providing safe patient care often requires precision and accuracy for measurements. Organizations have a responsibility to ensure that their devices are functioning properly to provide accurate data that drives medical interventions. Staff should be trained on the requirements for calibration and activities should be in place to ensure these required maintenance activities are kept current.

For more information regarding calibration of medical device requirements contact the C&A team at 704-573-4535 or email us at info@courtemanche-assocs.com.